Portable Appliance Testing, or PAT testing, is crucial for workplace safety, akin to a lighthouse guiding a ship through a storm. As an electrician, I’ve witnessed the consequences of neglecting this process. PAT testing serves as a vital safety measure, allowing us to detect and address electrical issues before they escalate into major incidents. But what makes it so vital, and what are the tangible advantages of consistent PAT testing? Let’s delve deeper into this key element of ensuring workplace safety.Let’s define Why PAT Testing Could Be the Missing Key to Workplace Safety.

It’s a potent tool in our safety arsenal, helping us identify and rectify electrical faults before they turn into catastrophic failures.

But why is it so critical, and what are the real, tangible benefits of regular PAT testing? Stick around as we peel back the layers on this crucial aspect of workplace safety.

Understanding Portable Appliance Testing

Diving into the realm of Portable Appliance Testing (PAT), it’s a comprehensive process conducted by proficient electricians to inspect, test, and certify the safety standards of movable appliances, whether they belong to IT, kitchen, medical, or scientific categories.

A comprehensive inspection is undertaken to identify any electrical hazards, thereby ensuring the equipment’s longevity and upholding safety standards.

Legal Compliance and Safety Obligations

While PAT testing isn’t explicitly a legal requirement, it plays a pivotal role in fulfilling an organization’s safety obligations under the Health & Safety at Work Act. Ensuring compliance with these obligations isn’t merely about ticking boxes; it’s about creating an environment where safety is paramount.

Regular electrical inspections, specifically PAT testing, can help uphold these safety standards. This meticulous process scrutinizes equipment safety, ensuring all portable appliances are free from defects that could pose a risk.

Fulfilling these health obligations is vital; it not only protects employees from potential hazards but also demonstrates a company’s commitment to maintaining a secure workplace. Thus, PAT testing plays an indispensable role in ensuring the safety and wellbeing of all individuals within an organization.

Role in Hazard Identification and Prevention

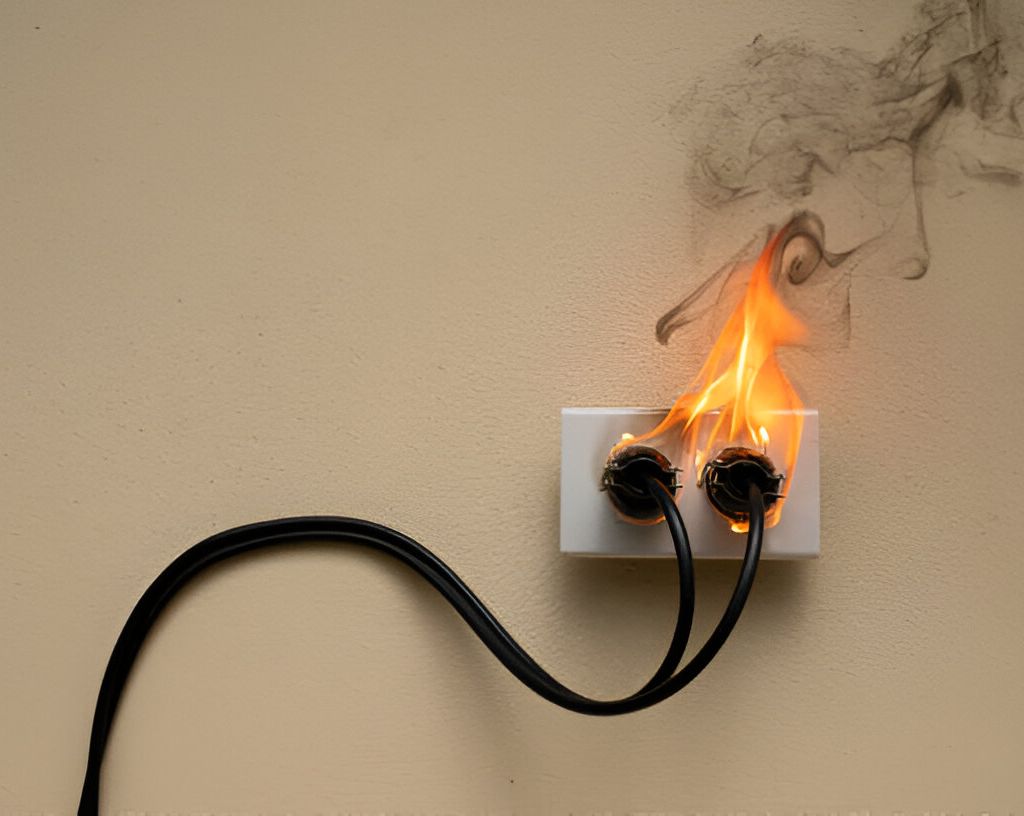

Building on the idea of safety compliance, PAT testing takes a proactive approach in hazard identification and prevention. This rigorous process is laser-focused on uncovering electrical hazards, such as faulty wiring or damaged plugs. These aren’t just minor inconveniences; they can lead to serious incidents like fires or electric shocks.

By regularly conducting PAT tests, these potential dangers can be identified and rectified early, significantly reducing the risk of accidents. So, PAT testing isn’t just about ticking a box for compliance, it’s an essential part of your organization’s safety measures. It’s about creating a safe environment, where everyone, from employees to visitors, can have peace of mind.

PAT Testing for Business Continuity

In the pursuit of seamless business operations, PAT testing plays a crucial role in preventing unforeseen equipment failures, thereby ensuring business continuity. It promotes equipment reliability, an essential element for maintaining operational resilience.

By identifying potential hazards early, PAT testing contributes significantly to risk mitigation and asset protection. This proactiveness helps to prevent costly disruptions and avert potential losses. Moreover, it provides an added layer of security, reinforcing the infrastructure’s resilience against unforeseen setbacks.

PAT testing, thus, underpins the foundations of business sustainability. In summary, PAT testing isn’t just about compliance or safety; it’s a strategic approach to preserving the continuity and sustainability of business operations. It’s an investment in reliability, resilience, and assurance.

Cost Savings and Equipment Lifespan

Beyond bolstering operational resilience, PAT testing also has a significant impact on cost savings and the lifespan of your equipment. The maintenance benefits are numerous, with a direct correlation between regular testing and longevity advantages.

When conducting a cost-effectiveness analysis, the investment protection provided by PAT testing is evident. It helps avoid the unexpected expenditure of premature equipment replacement, thus improving the bottom line. Moreover, PAT testing ensures lifespan extension of your appliances.

Consistent checks help detect potential issues early, allowing for timely repairs that prevent severe damage. In the long run, this practice not only saves money but also enhances the performance and extends the life of your equipment, proving PAT testing’s vital role in equipment management.

PAT Testing and Fire Safety Procedures

As we dive into the subject of PAT testing and fire safety procedures, it’s crucial to understand how this form of preventative maintenance can become an integral part of your business’s overall fire safety strategy.

It serves as a critical tool for fire prevention by identifying potential electrical hazards early on. These routine inspections, in adherence to safety standards, contribute significantly to electrical safety. They should be incorporated into your broader risk assessment strategy.

Furthermore, PAT testing isn’t only about equipment. It’s about people too. It’s pivotal to invest in employee training on the importance of electrical safety and the role of PAT testing in maintaining it.

This all-encompassing approach ensures a safe workplace, reducing potential fire risks.

Frequently Asked Questions

What Qualifications Does a Professional Need to Conduct Portable Appliance Testing (Pat)?

As a professional conducting PAT, I’m required to have specific qualifications including certification in electrical safety, solid knowledge of equipment, and training in regulatory compliance. These skills ensure safe, effective PAT testing.

How Often Should Portable Appliance Testing (Pat) Be Performed in a Typical Workplace?

As an expert, I’d recommend PAT testing annually in a typical workplace. This frequency upholds safety regulations, aligns with the maintenance schedule, and provides reminders for compliance benefits, ensuring a safer work environment.

How Do I Educate My Employees About the Importance of PAT Testing and Safe Use of Portable Appliances?

I’m committed to educating my team about PAT importance, emphasizing safety protocols and correct appliance handling. It’s essential they understand the role of testing in preventing accidents and maintaining a safe work environment.

What Kind of Appliances Are Considered ‘Portable’ and Require PAT Testing?

As an electrician, I’d clarify that portable appliances include anything unpluggable, from computers to kettles. Regulatory guidance doesn’t mandate non-portable PAT, but it’s crucial for safety to also test ‘non-portable’ fixed equipment.

What Are Some Common Faults or Issues That PAT Testing Can Help Identify and Rectify?

PAT testing helps identify common faults like faulty wiring and damaged plugs. It’s effective in rectifying these issues, reducing equipment dangers and ensuring workplace safety. It’s a crucial part of maintaining a safe environment.

Conclusion

In conclusion, PAT testing isn’t merely a legal requirement, it’s a crucial safety measure. It aids in early detection of potential hazards, ensuring the wellbeing of everyone in the workplace. Besides, it helps maintain business continuity and can even extend the lifespan of your equipment.

Investing in regular PAT testing is a smart move for any business. So, don’t overlook this vital process. Remember, safety should always be your top priority.